This method helps not only with better budgeting and cost control but also with setting competitive is shipping cost manufacturing overhead pricing strategies. Companies can get a better understanding of their total manufacturing expenses by accounting for indirect materials, indirect labor, utilities, and depreciation. Proper management of manufacturing overhead leads to more accurate budgeting and improved financial performance. Manufacturing overhead is made up of the indirect costs a company undertakes in its production process. Other expenses such as direct labor hours, materials costs, and similar items directly involved in the actual manufacturing process, do not fall under the category of manufacturing overhead.

Real-World Examples: Logistics vs. Materials Cost

Cambodia’s garment and footwear industry exports to the U.S. (which previously enjoyed low duties) now face nearly 50% tariffs, drastically raising costs. This change directly targets China’s real estate cash flow e-commerce supply chain as part of a strategy to combat illicit trade (like synthetic opioids) but also has broad implications for online retailers and consumers. Kickstarter creators using fulfillment services for Kickstarter campaigns need to balance low material costs with efficient logistics to avoid high shipping fees or delays.

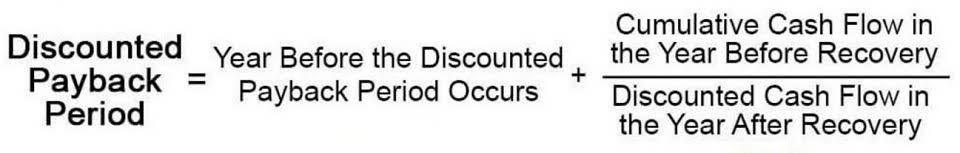

Predetermined Manufacturing Overhead Rate Formula

In order to know the manufacturing overhead cost to make one unit, divide the total manufacturing overhead by the number of units produced. Indirect labor is the cost to the company for employees who aren’t directly involved in the production of the product. For example, the salaries for security guards, janitors, machine repairmen, plant managers, supervisors, and quality inspectors are all indirect labor costs. Cost accountants derive the indirect labor cost through activity-based costing, which involves identifying and assigning costs to overhead activities and then assigning those costs to the product. Over the last few years, many ecommerce businesses have seen their products, components, and raw materials increase in price due to production hiccups and shipping delays impacted by the pandemic. Prototyping is an essential step in the development of electronic products.

Example #4: Indirect manufacturing costs (factory overheads)

- But manufacturing businesses can practice wise habits when it comes to managing their production costs.

- A final product’s cost is based on a pre-determined overhead absorption rate.

- Hence, every approach to reducing manufacturing overhead costs begins with a well-defined value stream map.

- The cost of direct labor is determined by multiplying the number of hours worked by the hourly rate.

- Therefore, understanding the different types of costs in manufacturing is crucial for any business owner or manager.

- Additionally, real-time tracking software aids in efficient supply chain management.

Lekan Olanrewaju is a content writer with years of experience in media and content creation. He has held positions at various media organizations, working with and leading teams at print magazines, digital publications, and television productions. HashMicro is Singapore’s ERP solution provider with the most complete software suite for various industries, customizable to unique needs of any business. Syspro is an ERP software that will benefit manufacturers and distributors. Industry can install Syspro’s features on any device, and it also provides implementation through the cloud, on-premise, or in a hybrid architecture.

Examples of Manufacturing Overhead Costs

Negotiating supplier contracts effectively can contribute to cost savings. Manufacturers aim to secure better deals on critical components and raw materials. Strong negotiation skills can lead to favorable terms and lower prices, impacting the production cost per unit positively. Establishing long-term relationships with suppliers also helps in securing stable prices for larger volume orders.

Manufacturing costs are essential in determining the profitability of a product. By calculating the manufacturing cost and comparing it to the selling price, businesses can determine the profit margin of the product. Understanding manufacturing costs is essential to manage costs effectively. Knowing the cost of each product enables businesses to set appropriate prices and identify areas where costs can be reduced.

- The consulting firm was also able to re-negotiate the manufacturing company’s contracts with poor-performing suppliers.

- Administrative costs are all the daily office costs required to keep your business running smoothly.

- Regular upkeep and unexpected repairs of manufacturing equipment are critical to avoiding downtime, especially in industries where production delays can lead to fines under supplier contracts.

- This is why it’s important to review and adjust your overhead calculations regularly.

- Semi-variable overhead expenses are costs that have a fixed baseline expense but may also fluctuate in relation to business activity.

- As you review these methods, ask yourself for each given product, will the allocated amount of overhead reflect the actual amount of overhead used in that item’s production?

Most warehouses and storerooms are full of salvageable pieces of old equipment just waiting to be found. Look for these safe-to-use, functional parts bookkeeping when a piece of machinery needs some repair. It might buy you some time before you need to spend all that money on a new piece of equipment.

Whether two goods are produced within a year inside a factory or a hundred goods are produced, the rent is static. Manufacturing overhead is also known as factory overheads or manufacturing support costs. Overhead costs such as general administrative and marketing costs are not included in manufacturing overhead costs. Factory rent and property taxes are significant components of manufacturing overhead. These costs are necessary for providing a physical space where manufacturing activities take place.